Not in reference to Top Gun, but the1983 film “Risky Business,” building science guru Joseph Lstiburek in his own inimitable style has this month published his latest Building Science Insight entitled “Risky Business : High Risk Walls.”

For anyone designing buildings that incorporate tilt-up concrete walls, particularly in the colder and temperate climate zones of Australia, and plan to insulate on the inside of the panel, this very readable paper is well worth taking a look at.

Unfortunately we have seen first hand this winter, such walls going badly wrong and suspect there will be more out there. Below is an extract from the edited version of this insight which first appeared in the ASHRAE Journal.

“As my friend Mac Pierce likes to point out: you could get a blindfolded drunk epileptic to cross Niagara Falls on a high wire without a net, but it wouldn’t be a good idea. There are some wall assemblies that are like that. One in particular irritates me. It has lead to a great deal of grief. It has problems that can easily be avoided. But simple analysis shows it works, and that is the rub. The simple analysis shows that it works, but the real world shows that it does not.

It gets better. More complicated analysis shows that it sometimes works, and truth be told, the real world shows that it also sometimes works. No moisture and exceptional workmanship can make it work. What are the odds? Clint Eastwood thermodynamics again: do you feel lucky punk? Well, do you?

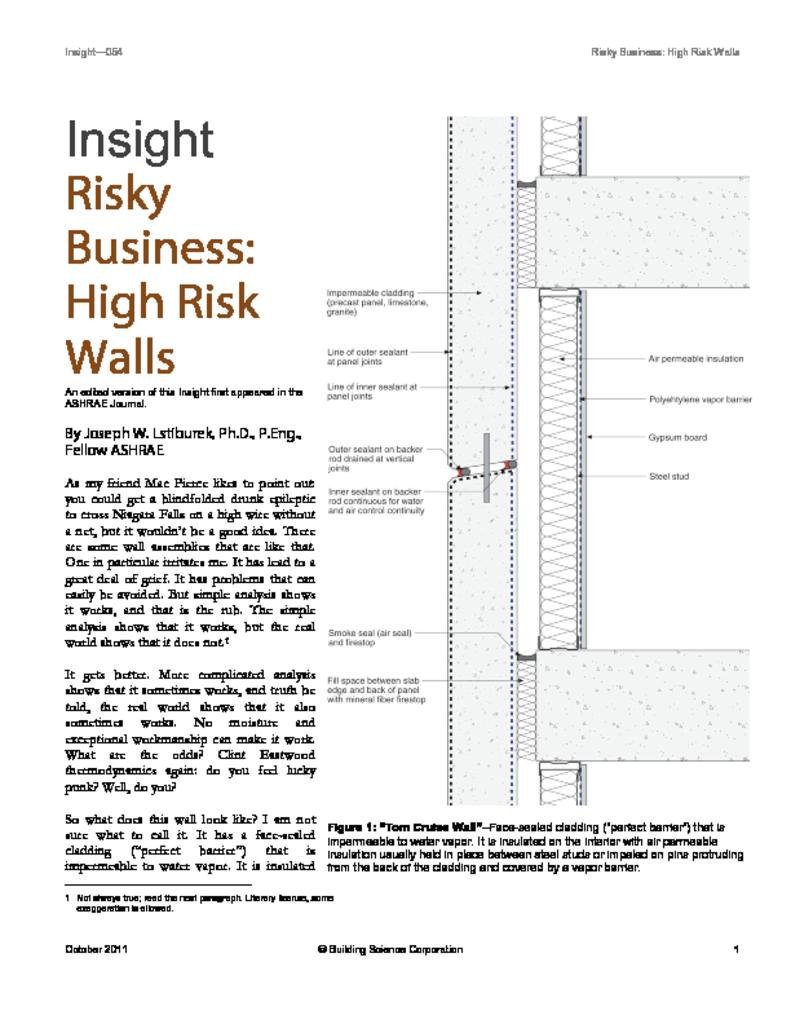

So what does this wall look like? I am not sure what to call it. It has a face-sealed cladding (“perfect barrier”) that is impermeable to water vapor. It is insulated on the interior with air permeable insulation usually held in place between steel studs or impaled on pins protruding from the back of the cladding and covered by a vapor barrier. Let’s call it a “Tom Cruise Wall.”

The insulation is typically a fiberglass batt “smushed” between steel studs. Sometimes, it is rockwool or mineral wool pinned to the interior of the exterior cladding. The fiberglass batt sometimes comes with a foil facing – the “vapor barrier.” More often the whole kit and kaboodle is covered with sheet polyethylene that may, or may not, be called an “air-vapor barrier.” Yuck.

So what is the problem? Well, the cladding is easy to make almost perfectly airtight and the interior lining is almost impossible to make airtight. That’s it? Really? That simple? Yup. You’re kidding. Everyone knows you can’t seal plastic sheets on the inside of wall assemblies and make them airtight.”

The full paper is available from www.buildingscience.com or directly by downloading here

The ‘Tom Cruise’ Wall High risk walls.

By Andy Russell

General Manager