ProctorGeo Vap 120

Product Description

ProctorGeo Vap120 is a light duty vapour and air retarder. The air & water vapour resistance of the two layer polyolefin non-woven membrane resists the flow of vapour by both diffusion and air movement through wall, ceiling and floor assemblies thus helping protect the building fabric and insulation from condensation and related problems such as mould, timber rot, corrosion and loss of thermal resistance.

When installed as a continuous layer, ProctorGeo Vap120 will help form an air tight layer improving the efficacy of ventilation systems thus improving the energy efficiency and the interior environment of the building enclosure.

Vapour retarder should be ProctorGeo Vap120 vapour retardant membrane, tested to AS/NZS 4200,1:1994 standards, secured in accordance with product user guide.

* ProctorGeo Vap 120 is classified as light duty in accordance with the value specified for bursting strength.

** Testing to AS1530.2. has only been conducted on sections of material without integrated tape

Applications

Vapour retarders are typically used with sheet roof and wall claddings, in constructions located in cold climates, buildings with high internal humidity such as indoor swimming pools and museums, air conditioned buildings located in hot and humid climates and refrigerated buildings such as cold stores and ice rinks.

A correctly specified and installed vapour retarder can limit the volume of water vapour reaching condensing surfaces. Users need to understand, based on the climate location, building use and other factors, if and why a vapour retarder is required and that it is correctly located relative to any insulation.

Vapour retarders should not be used on the exterior side of insulation in cold and temperate climates as a sarking where there is a risk that condensation will form on the interior face of the retarder. Please contact Proctor Group Australia for advice on the suitable application of ProctorGeo Vap120.

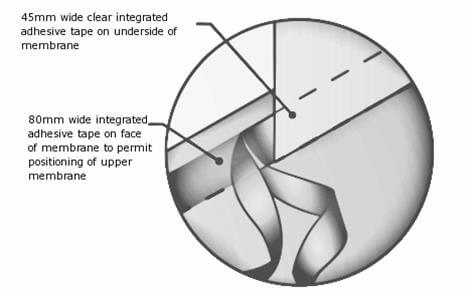

Integrated Tape

To improve the integrity of installation, ProctorVap 120 is supplied with a factory applied integrated tape on both the outer face of the lower course and rear face of the upper membrane.

Benefits

- Ideal for swimming pools and humid buildings

- Factory applied integrated tape

- Slightly translucent for ease of insulation

- Water vapour resistant

- Suitable for use in some corrosive environments

- High water resistance

- Non perforated

- Non conductive

- Air tight

- Lightweight and easy to handle

- Robust with excellent tear resistance

Sample Specification

Vapour retarder should be ProctorGeo Vap120 vapour retardant membrane, tested to AS/NZS 4200,1:1994 standards, secured in accordance with product user guide.

Vapour resistance: No less than 40MNs/g

Duty classification: Light

Water Barrier Classification: High

Emmitance: Non-reflective

Flammability Index: Low

Notes: Non conductive and not subject to corrosion