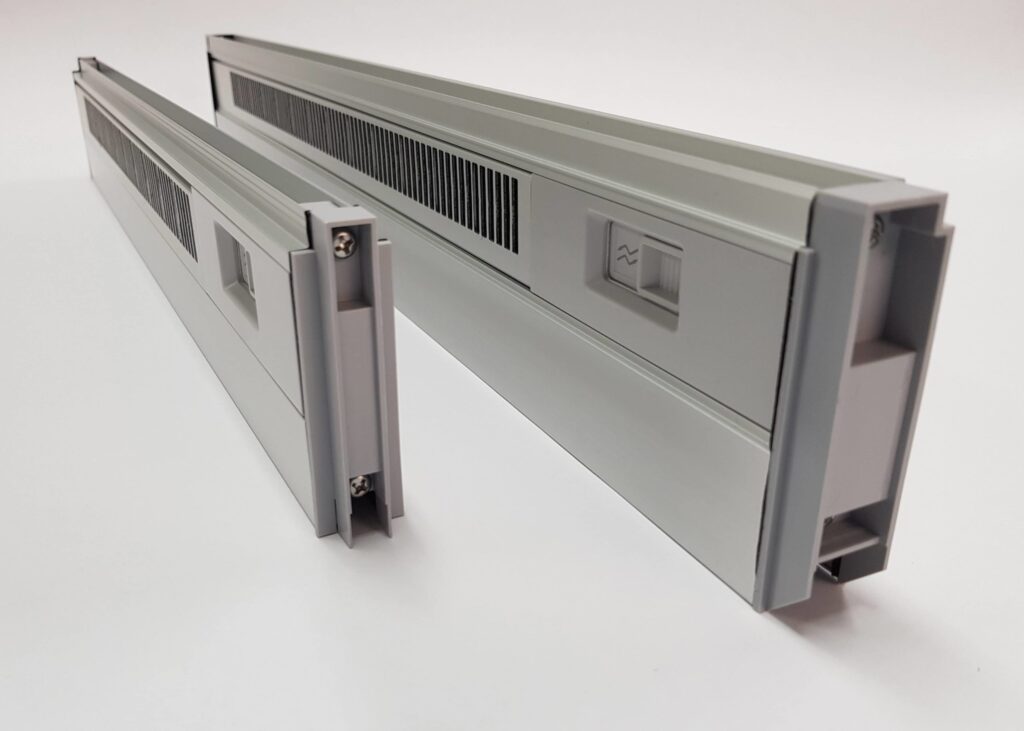

Ventient Trickle Breathe (TB)

Glazed-in trickle vent

Product Description

The Ventient Trickle Breathe (TB) is precision manufactured aluminium glazed-in trickle vent that can be accommodated into a wide range of window frames.

Applications

Improvements in construction create buildings that are more airtight than previously, with the result that infiltration or leakiness is no longer providing a pathway for make-up air for exhaust systems.

Although many building are complying with building code requirements by having sufficient operable windows, changing lifestyle patters, concerns about noise and security and generational differences mean that ventilation from open windows tends to be infrequent.

Unlike conventional systems such as operable windows or louvres, Proctor Ventient TB can get on with the job of providing fresh air circulation regardless of occupancy.

As part of the total ventilation system Proctor Ventient can provide continuous ventilation to spaces even if they are unoccupied and is perfect for student accommodation, hotels, age care, healthcare and educational facilities.

Ventient is an ideal solution for residential buildings such as modern air tight homes and medium or high rise developments, as modern lifestyles mean that occupants are unable to mange purge ventilation and often return home to a stuffy environment.

Installation

The Ventient TB is installed into the glazing pocket of the frame, in accordance with the product installation guide.